Telephone: 379 14 89 430

Opening hours: Monday to Friday, 9:00 a.m. to 6:00 p.m.

Prototyping and 3D Printing, what a match!

13 August 2022

With today’s technology, the 3D printing process has become easier than ever. There are 3D printers for every budget, and even the inexpensive ones promise excellent results if set up correctly and following the right steps.

There are 3D printers that take advantage of different technologies, but, especially at the consumer level, there are two technologies in particular: resin printing and filament printing (FDM).

The resin printer uses a polymer-based compound that solidifies when irradiated by ultraviolet rays. A UV illuminator projects UV rays onto a high-resolution monochrome LCD screen. The resin sticks to the build surface, a step-motor removes it from the FEP and proceeds with the next layer.

In Resin printers, the material is almost invariable. In FDM printers, on the other hand, the rolls can be of different materials: PLA, Nylon, ABS, PETG, etc. Each of these materials has different physical properties.

FDM printers are best suited for mechanical, electrical and general industrial prototyping due to the high strength of the printed parts.

In fact, by printing two identical objects on the two printers and trying to drop these objects from a certain height, resin printing is more like porcelain than plastic. FDM prints (when printed solidly) are very durable and can be used to prototype mechanical parts.

I am a proud owner of 5 3D printers of which 2 are resin printers, 2 are FDM printers, and the last one is a multifunction printer that allows you to change tools for milling or laser cutting.

What can 3D printing be used for?

Some examples…

To repair broken mechanical parts. Just recently I rebuilt the locking mechanism of my dishwasher that had broken.

To inventing new ones. Do you need a pen holder? What’s the point of leaving the house? Design it any way you like and print it out with not even 1€ worth of materials.

Professional uses of course are different. Let’s go and look at some of them…

Design of DOMO

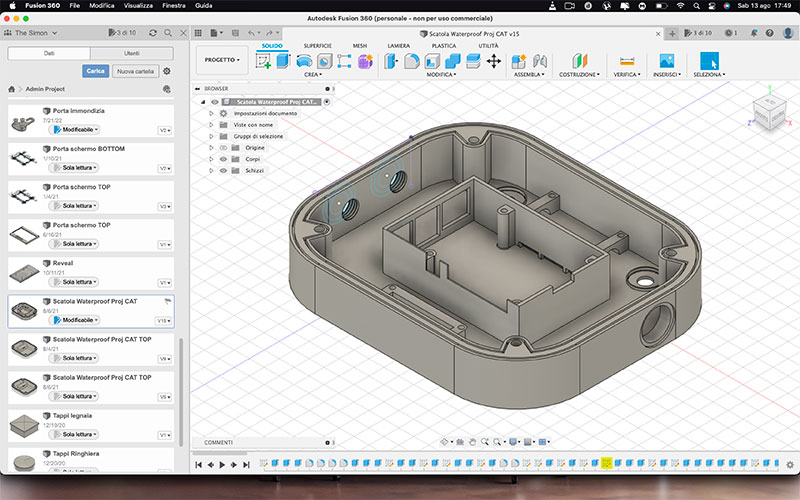

DOMO’s Fusion 360 project

Shown in the image is the anti-water container of DOMO’s electronics. Our IoT remote control prototype for hospitality facilities.

Easily identifiable in the center is the housing area for a Raspberry PI4, two holes for the insertion of water-proof connectors, and the hole for the power button for the control unit. On the sides are slots for inserting the water-proof gaskets.

Gaskets can also be safely 3D printed using a special filament whose material is called TPU.

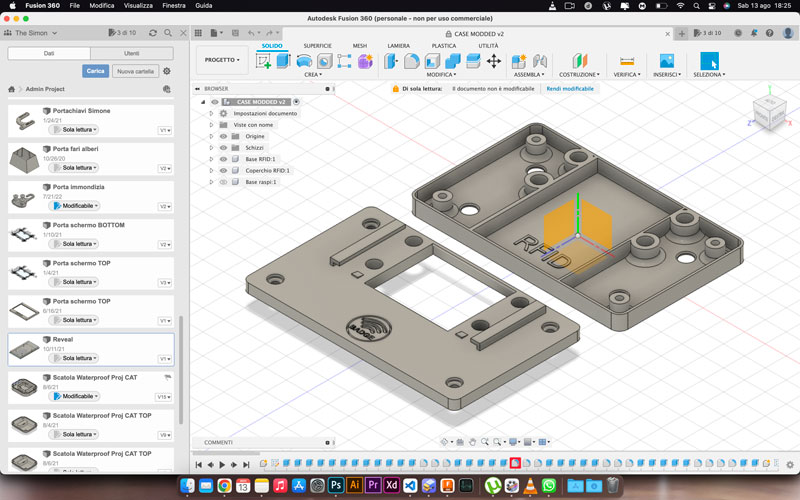

Time and attendance module design

We are currently working on this project to be provided on loan for use to medium and large companies that join our employment consulting services. It is an enterprise attendance tracking module based on the integration of an RFID reader.

Employees, equipped with the RFID TAG, will be able to easily record their check-in and check-out by passing the TAG near the reader.

Automatically, an API call will be made to our Cloud microservice that will record the employee’s attendance within our databases.

This will make coupon processing much faster and will not create delays in their delivery.

Conclusions

As you have seen, the uses of 3D printing are truly many and limited only by one’s imagination.

Keep following our articles on the world of technology.

[starbox]